| Name: | Triangle shape coriolis mass flow meter |

|---|---|

| Measuring Range: | 0-10t/h |

| Process Connection: | DN10~25 |

| Accuracy: | 土0.10% |

| Working temp: | -200~ 350℃ |

| Working pressure: | 1.6MPa 4.0MPa |

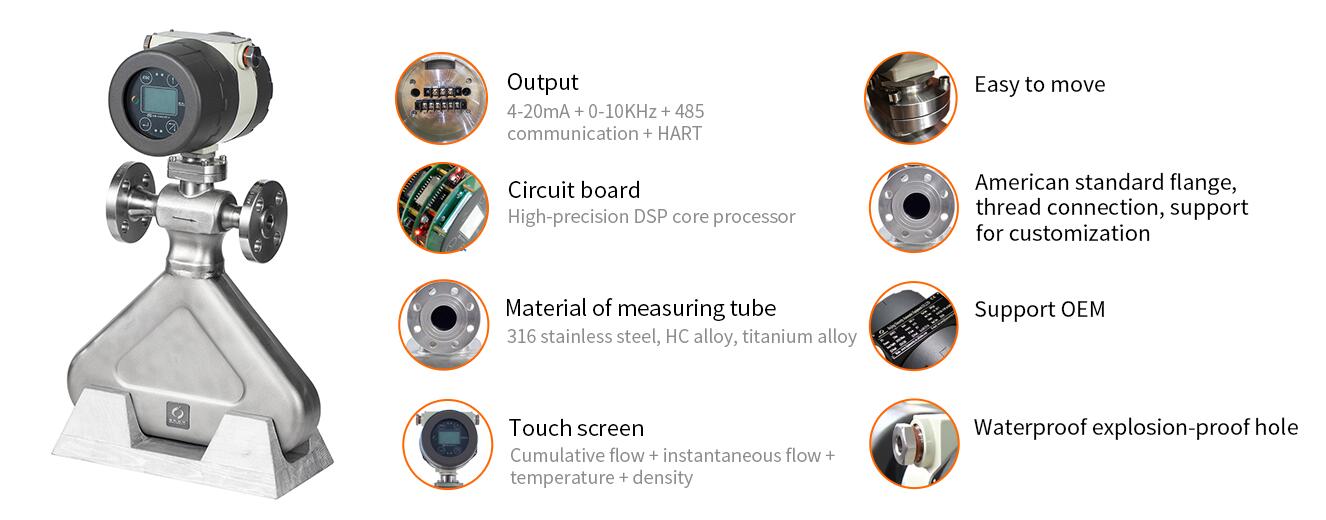

| Output: | 4-20mA, RS485 Modbus RTU,HART |

| Explosion proof: | Exd ib ll CT6 Gb |

Flow Range | See charts below |

Connection | ANSI, DIN, JIS, or Sanitary Tri-Clamp flanges, etc. ( Connections can be customized) |

Maximum Pressure | 16 bar (230 psi), [Optional 40 bar (580 psi), up to 1000 bar (14504 psi)] |

Body Material | 304 Stainless Steel |

Measuring Tube Material | 316 L SS, HC Hastelloy, 316L SS + PTFE, HC + PTFE, etc. ( materials can be customized) |

Process Temperature Range | |

Integrate Type | -50 to 15°C (-58 to 302°F) |

Remote Type (-R) | -50 to 35°C (-58 to 662°F) |

Ambient Temperature | -40 to 55°C (-40 to 131°F) |

Working Humidity | (5 to 95%) RH at 25°C (77°F) |

Flow Accuracy | 0.2/ 0.1/ 0.05% (Liquid), 0.5% (gas) |

Density measuring | |

Range | 0.2 to 3.0 g/cm3 |

Error | ± 0.002 g/cm3, ± 0.001 g/cm3 |

Repeatability | 0.001 g/cm3 |

Temperature Accuracy | ±1.0°C |

Protection | IP67 |

Approvals | ATEX, CE, ISO9001, ISO14001, OHSAS18001 |

Communications | RS485 (RTU Modbus), HART (-HART option) |

Pulse Output | 0 to 10 kHz |

Current Output | 4 to 20 mA |

Power Supply | 24VDC, 220VAC (universal power source option) |

Triangle shape coriolis mass flow meter

● Triangle shap bent tube design

● For all industries, and all process and custody transfer applications.

● Universal measuring principle for liquids and gases

● Multivariable measurement- simultaneous measuring of mass flow, density, temperature

● High measuring accuracy: typically ±0.2%, ±0.1% o.r., optionally: ±0.05%

● Measuring principle independent of the physical fluid properties and the flow profile

● Easy to install (low risk of gas bubble inclusion)

● No recalibration required after fluid change

● No installation straight line necessary

● No temperature or pressure compensation necessary

● No periodical recalibration required

The mass flowmeter consists of a sensor and a transmitter. The mass flow meter is equipped with digital signal processor (DSP) -based digital transmission equipment, and integrates digital closed-loop vibration control (DLC) signal processing, sensor calculation and diagnostic functions, and has high measurement accuracy and extensive capabilities. And excellent reliability for you. On-line node configuration, fault diagnosis and data logging can be performed directly through HART or PC via Modbus to communicate with the communicator. The flow meter will not only calculate the process volume flow, cumulative volume and component ratio. TS series flow meters can also provide mass flow, density and temperature online in real time.

Coriolis mass flow meters are the most accurate measuring method in the world. The Coriolis measuring principle is used in a wide range of different branches of industry, such as the life sciences, chemicals, petrochemicals, oil and gas, food, and- no less importantly - in custody transfer applications. Coriolis flowmeters can measure virtually all fluids: cleaning agents, solvents, fuels, crude oil, vegetable oils, animal fats, latex, silicon oils, alcohol, fruit solutions, toothpaste, vinegar, ketchup, mayonnaise, gases or liquefied gases.

The Sincerity DMF series U-shape is the standard high performance coriolis mass flowmeters for the process industry. The U shape bent tube meter offers superior performance and high accuracy in virtually any application. From process control in (petro) chemical applications to concentration measurements in the food and beverage industry to custody transfer filling and transport measurements in the oil and gas industry. Its high-end options also make the DMF-1 Series U-shape the optimum device for cryogenic media like Liquefied Natural Gas (LNG) with temperatures down to -200°C / -392°F as well as applications involving high operating temperatures (up to 350°C / 662°F) or pressures (up to 1000 barg / 14504 psig).

Coriolis flow measuring principle

Each Coriolis flowmeter has one or more measuring tubes which an exciter causes to oscillate artificially. As soon as the fluid starts to flow in the measuring tube, additional twisting is imposed on this oscillation due to the fluid’s inertia. Two sensors detect this change of the tube oscillation in time and space as the “phase difference.” This difference is a direct measure of the mass flow.

In addition, the fluid density can also be determined from the oscillation frequency of the measuring tubes. The temperature of the measuring tube is also registered to compensate thermal influences. The process temperature derived from this is available as an additional output signal.

How does a Sincerity Coriolis flow meter measure mass flow and density?

Coriolis mass flow measurement is the MOST ACCURATE FORM for a flow measurement for a wide range of industrial processes. Each Coriolis flowmeter has one or more measuring tubes.

As soon as the fluid starts to flow in the measuring tube, additional twisting is imposed on this oscillation due to the fluid's inertia. Two sensors detect this change of the tube oscillation in time and space as the “phase difference.”

Phase difference= mass flow

Oscillation frequency= density

General

- Liquids with transient gas entrainment

- Cryogenic or high temperatures (-200…+400°C /-328…+752°F)

- Super critical gases

- Custody transfer (CT)

Chemical and other process industries

- Concentration and density measurement

- Bulk loading

- Batching and blending to reactors

- Hydrocarbon cracking

Oil and gas industry

- Metering skids, bulk loading, pipeline transfer

- "Bypass" density measurement

- Liquefied Natural Gas (LNG)

- Bulk loading

- In-line density measurement

- Multiphase measurement in upstream applications

Food and beverage industry

- Batching, dosing, filling

- Mass flow measurement of ice cream and milk (e.g. at the raw milk reception)

- Measurement of flow, density, specific gravity in brewing processes - Dosing of hop extract

- Measurement of Brix, density and flow in fruit juices

- Dosing of natural oils, grease, vegetables (e.g. spinach) etc.

- CO2 injection in soft drink production

Pharmaceutical industry

- Batching, dosing, filling

- Solvent extraction

Marine industry

- Bunkering and fuel consumption measurement

Pulp and paper industry

- Additives, bleaches and colourants

- Crystallising, solidifying and cryogenic products